- inCAD Library Home

- > No.000109 Feeding Mechanism

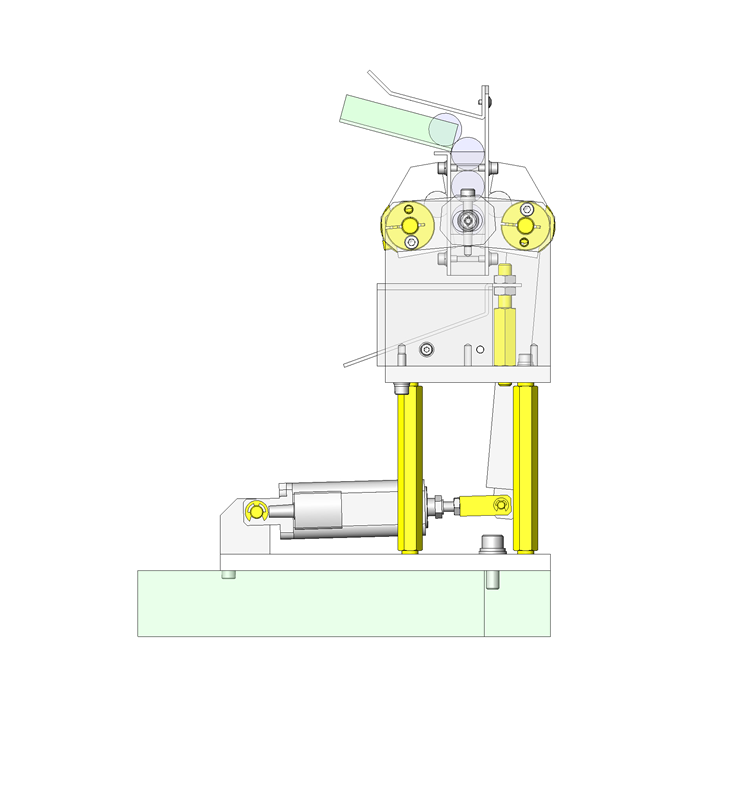

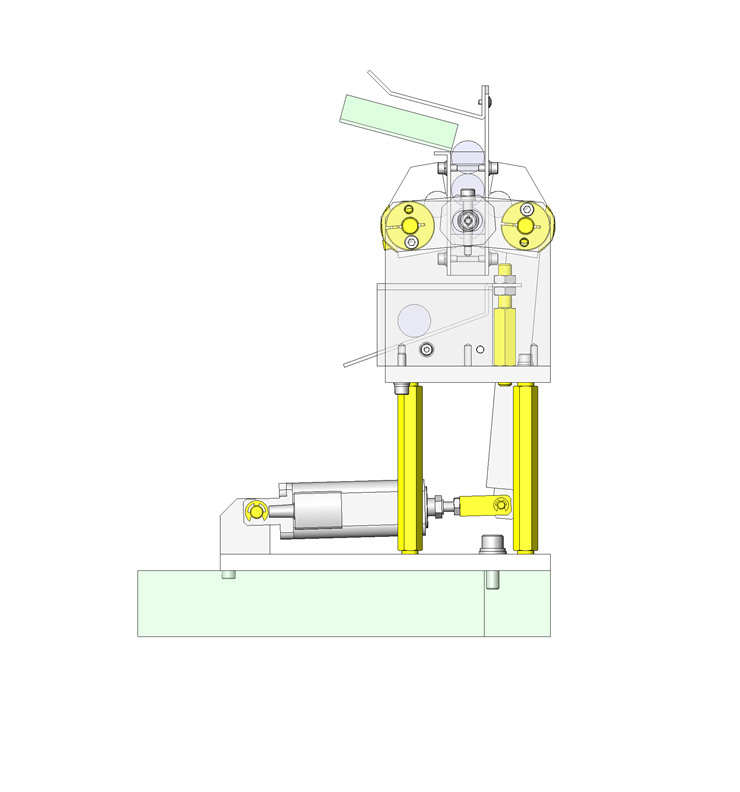

No.000109 Feeding Mechanism

40

40

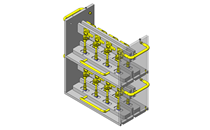

Stops and separates round bars in one step.

Related Category

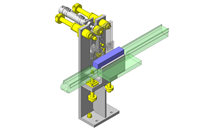

- * Unit assembly CAD data consists of some sub-assemblies.

Each sub-assembly unit can be used as it is or can be edited.

Application Overview

Purpose

- Purpose

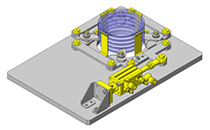

- To separate and transfer cylindrical workpieces.

- Operation

- The electric actuator is used to operate the arm and claws, which separate the workpieces one by one.

Target workpiece

- Aluminum roller.

- Size: Ø20 x L200mm.

- Weight: 170g.

Design Specifications

Operating Conditions or Design Requirements

- Claw rotation angle: 10°

- Cylinder stroke: 30mm.

Selection Criteria for Main Components

- An electric cylinder with a 30mm stroke is selected to rotate the claws by 10 degrees.

Design Evaluation

Verification of main components

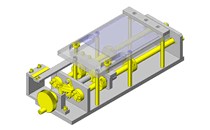

- Verify whether the robot cylinder has a speed high enough to make the cam perform workpiece separation.

- Confirmation of robot cylinder speed.

- Conditional value: gravitational acceleration g = 9.8N/m², stroke of robot cylinder that rotates cam at rotation angle of 10°: L0 = 29.6mm,

Equation of free-fall motion (when initial velocity is Vo = 0, t = elapsed time [sec], h = displacement amount [m]), velocity: V = G x t, displacement amount: h = 1/2 x t², elapsed time: t = √(2 x h/g)

State (1): The lower part of cam is closed and the lowermost workpiece is stopped.

State (2): The lower part of cam is opened and the lowermost workpiece and the next workpiece start dropping.

State (3): The lower part of the cam is completely opened and the next workpiece is stopped by the stopper.

Displacement amount of next workpiece between state (2) and state (3): h = 4.4mm = 0.0044m,

Stroke of robot cylinder that rotates cam at rotation angle of 0.8° between state (2) and state (3): L1 = 2.37mm,

Elapsed time during this period: t = √(2 x h/g) = √(2 x 0.0044/9.8) = 0.03 sec

Required cylinder speed calculated from robot cylinder stroke and elapsed time: Vs = L1/t = 2.37/0.03 = 79mm/sec

As this speed is within the robot cylinder maximum speed of 100 mm/sec, the next workpiece is stopped and workpiece separation is possible.

- Conditional value: gravitational acceleration g = 9.8N/m², stroke of robot cylinder that rotates cam at rotation angle of 10°: L0 = 29.6mm,

Other Design Consideration

- Due to the lack of an air pressure source, an electric cylinder is used.

- The height of the shoot is designed to be adjusted using the external threads of hex posts and nuts.

Explore Similar Application Examples

Page

-

/

-