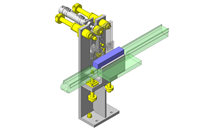

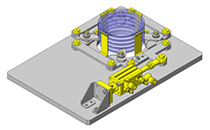

Cylinder with Twin Guides

| Product name | Cylinders with Twin Guides |

| Part number | MGCLF16-20 |

| Features | Cylinders having the guides on both ends for usability. |

* Orange colored cells in the table below indicate the part numbers used in this example.

Selection criteria

Guided type, size and stroke.

Back to page top

Available sizes

■Cylinder with Guides (Fixed stroke type)

Bore

dia. | Bearing | Slide bearing | Linear bushing bearing | Cylinder width

(mm) | Overall length

(Below +St) | Thickness

(mm) |

| St | 10 | 20 | 25 | 30 | 40 | 50 | 75 | 100 | 10 | 20 | 25 | 30 | 40 | 50 | 75 | 100 |

| Ø12 | ○ | ○ | - | ○ | ○ | ○ | ○ | ○ | ○ | ○ | - | ○ | ○ | ○ | ○ | ○ | 56 | 39 | 22 |

| Ø16 | ○ | ○ | - | ○ | ○ | ○ | ○ | ○ | ○ | ○ | - | ○ | ○ | ○ | ○ | ○ | 62 | 43 | 25 |

| Ø20 | - | ○ | - | ○ | ○ | ○ | ○ | ○ | ○ | ○ | - | ○ | ○ | ○ | ○ | ○ | 72 | 47 | 30 |

| Ø25 | - | ○ | - | ○ | ○ | ○ | ○ | ○ | - | ○ | - | ○ | ○ | ○ | ○ | ○ | 86 | 47.5 | 38 |

| Ø32 | - | - | ○ | - | - | ○ | ○ | ○ | - | - | ○ | - | - | ○ | ○ | ○ | 112 | 48 |

| Ø50 | - | - | ○ | - | - | ○ | - | ○ | - | - | - | - | - | - | - | - | 146 | 72 | 60 |

Back to page top

Selection steps

■Cylinder selection steps

1, Define various load conditions

↓

2, Calculate cylinder output. (in case of double acting cylinder)

↓

3, Determine bore dia.

↓

4, Determine theoretical reference speed

↓

5, Verify cylinder's cushion mechanism

6, Verify lateral load applicable on the cylinder

Back to page top

Accuracy Info

■Non-rotating accuracy of guided cylinder

Non-rotating accuracy: Looseness by guide rod and bearing clearance represented in a rotation angle centered on the piston rod.

Bore

dia. | Non-rotating accuracy of tip link bar |

| Slide bearing | Linear bushing bearing |

| Ø12 | ±0.12° | ±0.06° |

| Ø16 | ±0.10° | ±0.06° |

| Ø20 | ±0.09° | ±0.05° |

| Ø25 | ±0.08° | ±0.05° |

| Ø32 | ±0.06° | ±0.04° |

| Ø50 | ±0.05° | - |

Back to page top

Performance info.

■Theoretical force

(N)

Bore dia.

(mm) | Operation direction | Applied pressure (MPa) |

| 0.4 | 0.5 |

| 12 | Push side | 45 | 57 |

| Pull side | 34 | 42 |

| 16 | Push side | 80 | 101 |

| Pull side | 60 | 75 |

| 20 | Push side | 126 | 157 |

| Pull side | 94 | 118 |

| 25 | Push side | 196 | 245 |

| Pull side | 151 | 189 |

| 32 | Push side | 322 | 402 |

| Pull side | 241 | 302 |

| 50 | Push side | 785 | 982 |

| Pull side | 660 | 825 |

■ Allowable lateral load

(N ・ m)

Bore dia.

(mm) | Stroke (mm) |

| 10 | 20 | 25 | 30 | 40 | 50 | 75 | 100 |

| 12 | 24 | 19 | - | 16 | 14 | 12 | 37 | 31 |

| 16 | 40 | 33 | - | 28 | 24 | 21 | 55 | 46 |

| 20 | - | 52 | - | 45 | 39 | 35 | 55 | 46 |

| 25 | - | 69 | - | 60 | 52 | 47 | 73 | 62 |

| 32 | - | - | 166 | - | - | 131 | 107 | 91 |

| 50 | - | - | 296 | - | - | 245 | - | 241 |

Back to page top

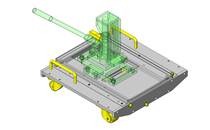

Sensor for Cylinder

| Product name | Sensors for Cylinders |

| Part number | MD13L3 |

| Features | Sensors dedicated for Double Acting Cylinder |

* Orange colored cells in the table below indicate the part numbers used in this example.

Selection criteria

Sensors dedicated to selected cylinder

Back to page top

Available sizes

■Sensor for cylinder

Cable length

(m) | Sensor type | Number of leads | Lead wire exit direction |

| 1, 3 | With contacts | 2 wires | Back |

| 1, 3 | No contacts | 3 wires |

| 1, 3 | No contacts | 2 wires |

| 1, 3 | No contacts | 3 wires | Top |

| 1, 3 | No contacts | 2 wires |

Back to page top

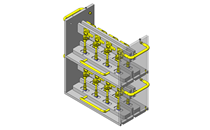

Flow Rate Control Valve

| Product name | Flow Rate Control Valves/90 Deg. Elbow/Standard |

| Part number | SPSNL6-M5 |

| Features | Speed Controllers capable of adjusting the flow rate of compressed air. |

* Orange colored cells in the table below indicate the part numbers used in this example.

Selection criteria

To match selected cylinder size and to control cylinder stroke speed

Back to page top

Available sizes

■Flow Rate Control Valve

| Material | Control type | Color |

| Black | White |

Polybutylene terephthalate

Threads: EN 1.4301 Equiv. | Meter-out | ○ | ○ |

Polybutylene terephthalate

Threads: Brass | Meter-out | - | - |

| Meter-in |

■Sizes and Dimensions

Bore dia.

(mm) | Thread size |

|

| 4 | M5 |

| 1 |

| 6 | M5 |

| 1 |

| 2 |

| 8 | 1 |

| 2 |

| 3 |

| 10 | 2 |

| 3 |

| 4 |

| 12 | 3 |

| 4 |

Back to page top

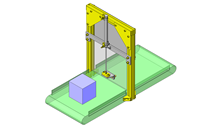

IDEA NOTE Chuck with clearances

No force is applied to workpiece due to gripping fingers design.