- inCAD Library Home

- > No.000239 W reversing mechanism

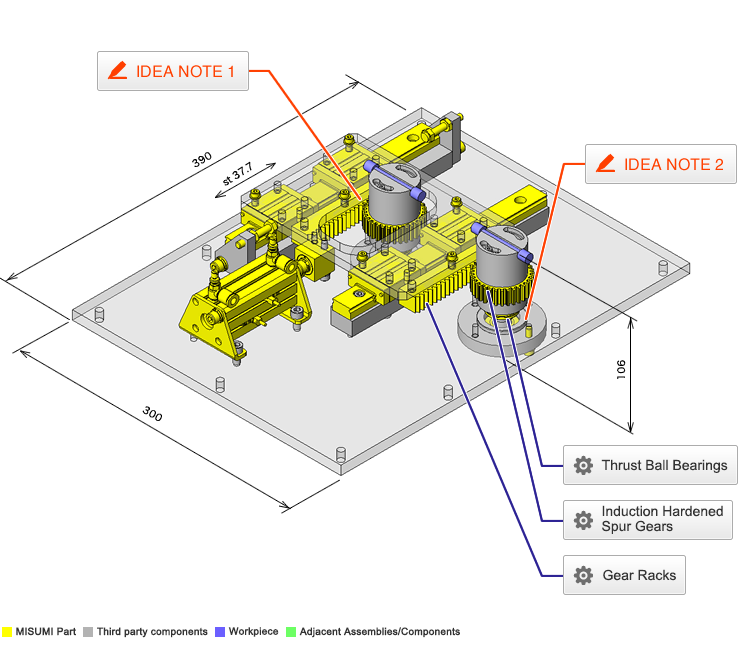

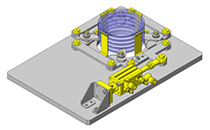

No.000239 W reversing mechanism

58

58

Angled rack and pinion mechanism used to reverse a workpiece.

Related Category

- * Unit assembly CAD data consists of some sub-assemblies.

Each sub-assembly unit can be used as it is or can be edited.

Application Overview

Purpose

- One axis of the linear rack section is driven by a cylinder, the pinions on the other axis are then rotated simultaneously to reverse them to any desired angle. (90° in the example).

Points for use

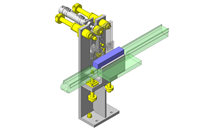

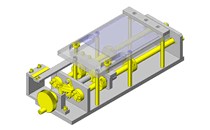

- The workpiece is transferred in and out by the up and down motion of the chucking mechanism on the external unit.

- The stroke is controlled by both the sensor of the cylinder, and a mechanical stopper to ensure the precise workpiece angle.

Target workpiece

- Material: Resin

- External Shape:Ø9 x W41mm

- Mass: 3g

Features

Operating specifications ・ Dimensions

- Workpiece rotation angle: 90°

- Pinion Gear: m1.5, z32, P.C.D. 48mm

- Required Cylinder Stroke: 37.7mm

- System External Shape: W 390 x D 300 x H 106mm

Required accuracy ・ Load

- Cylinder Thrust: 6.83N or more

Selection criteria of main components

- Cylinder

- Adopted thin type cylinder for space saving.

- Pinion Gear

- A pinion gear with a tap hole is used affixed to workpiece jig, so the jig can be rotated.

Design point

Calculation processes for the main components

- Whether the cylinder thrust force can handle the slide-way load and rotation section load is verified below.

- Thrust of cylinder (Ø20mm, ST 50mm)

- Condition value: Slide way total weight m1 = 1.714kg, linear guide friction coefficient μ1 = 0.005 (from catalog), rotating section total weight m2 = 0.688kg, conversion factor to slide motion of rotating section μ2 = 1 (assumed as a slide with a friction coefficient of 1 for safe side), operating pressure of cylinder: 0.2MPa

- Slide way load: F1 = m1 x g x μ1, thus, F1 = 1.714 x 9.8 x 0.005 = 0.084N

- Rotating section load: F2 = m2 x g x μ2, thus, F2 = 0.688 x 9.8 x 1 = 6.742N

- Total load: F = F1 + F2 = 0.084 + 6.742 = 6.83N

- Pull side thrust of cylinder: F0 = 47N(from catalog)

- Safety factor: F0/F = 47/6.83 ≈ 6.88

Structure elaboration and design key points.

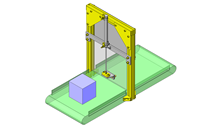

- This system is effective for a corner section, that requires the reversing of multiple parts on an automated line in single file.

- The workpiece table has a slotted hole in the rotated direction in order to enable the adjustment of the workpiece position during rotation.

- Installing a sensor and mechanical stopper in parallel enables precise positioning and angle adjustment of the workpiece. It also reduces the generation of moments by stopping the transmission of cylinder thrust prior to hitting the mechanical stopper.

Explore Similar Application Examples

Page

-

/

-