- inCAD Library Home

- > No.000068 Conveyor with escapement

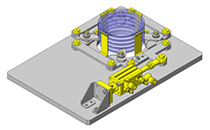

No.000068 Conveyor with escapement

39

39

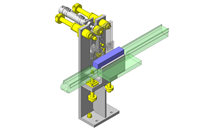

Escapement mechanism for gravity conveyor

Related Category

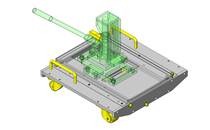

- * Unit assembly CAD data consists of some sub-assemblies.

Each sub-assembly unit can be used as it is or can be edited.

Application Overview

Purpose

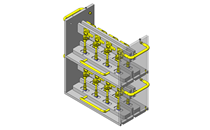

- Design simple and low cost conveyor that requires no motor power sources but utilizes gravity (weight of the material) to move the load.

- Points for Use

When the cylinder head is raised:

The first workpiece is moving along cantilever arm and is stopped by the cylinder. At that time: back of the cantilever arm moves up and stops the second workpiece. Second workpiece is also sitting on the catilever arm.

When the cylinder head is lowered:

First workpiece moves to next position using gravity and incline of cantilever arm. At the same time the back of the cantilever arm is pulled back by spring to its home (horizontal) position. At the same time cylinder head raises up and second workpiece using gravity moves forward untill it hits cylinder stopper head.

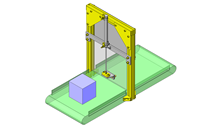

Target workpiece

- Cardboard box filled with products.

External dims.: W170 x D120 x H195

Workpiece weight: 5.0kg

Design Specifications

Operating Conditions or Design Requirements

- Motion stroke: 250mm

- External dimensions: W600 x D260 x H346

Required Performance

- Total weight of components occupying conveyor: 100N

Selection Criteria for Main Components

- Tension spring

- A tension spring is used to return the cantilevered to the down position.

- Cylinder with guide

- Used as stop of initial (first) workpiece.

- Shock absorbing stopper

- Bumper with low elasticity rubber is selected to absorb shocks on parts.

- Engineering plastic bearing

- Select a type with ample load capacity.

Design Evaluation

Verification of main components

- Verify if the spring can actuate the cantilever arm according to the position of the material (workpiece) on the rollers.

- Tension spring load

- Loads and spring deflection of cantilever arm varies with workpiece position

(1) Load F1 (N) - when workpiece is sitting on the top of the front roller

(2) Load F2 (N) - when back of cantilever arm is completely raised up

(3) Load F3 (N) - when workpiece is not - Formula: Reaction force F = kx + Initial tension

- Spring constant: Temporarily select k = 1.32N/mm

- Initial tension = 4.71N

- Max. designed deflection amount: x = 12mm (when set 1mm, when stroked 12mm)

- (1) is,

(1) F1 = 50N ⇒ Supported in 2 places, 25N

(2) F2 = 1.32N/mm x 12mm + 4.71N = 21N

(3) F3 = 1.32N/mm x 1mm + 4.71N = 6N

Therefore (1) > (2) > (3) holds and selected spring constant k = 1.32/mm is correct.

- Loads and spring deflection of cantilever arm varies with workpiece position

- Cylinder w / guide

- Cylinder is used as a stopper.

- Workpiece weight 5kg < 30kg (Max. weight)

- Conveyance speed 15m/min < 30m/min (Max. speed)

Therefore, the range is suitable.

- Engineered plastic bearing

- Since one workpiece is supported by 6 bearings,

load on each bearing = 50N / 6 ≈ 8.5N

therefore 8.5N < 176N (Load capacity)

- Since one workpiece is supported by 6 bearings,

Other Design Consideration

- Since the tension spring is mounted on frame slots, tension adjustments are possible.

- When the load travels on the conveyor, front and rear rollers of the cantilevered arms are moving by contacting the load.

- Since the conveyor rollers are mounted on the extruded Aluminum frame slots, roller pitch can be adjusted.

- The cantilevered arms are coupled together so right and left actuation is synchronized on individual load points.

- In order to reduce the friction on the load as it moves down the conveyor resin rollers are used.

Explore Similar Application Examples

Page

-

/

-