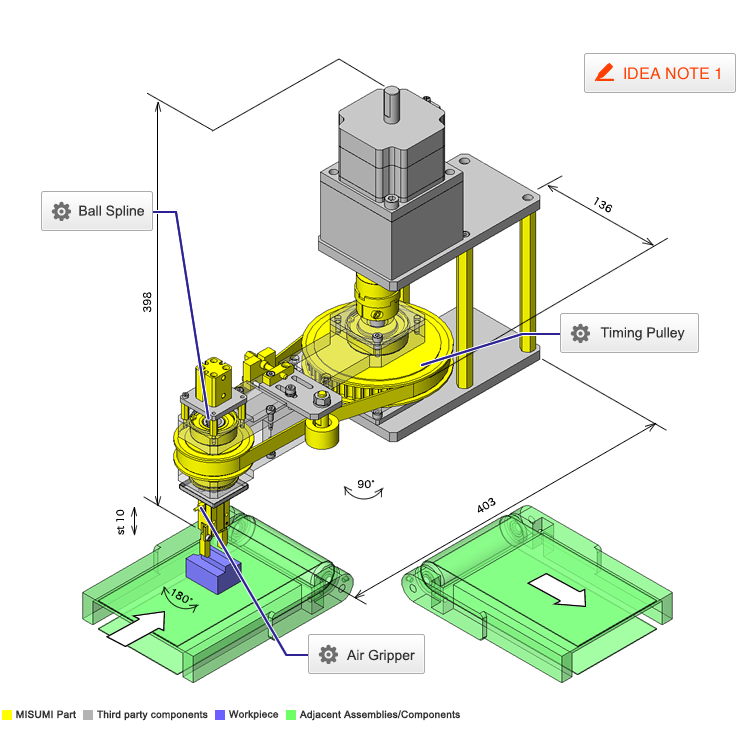

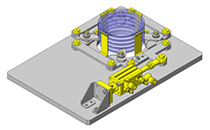

Timing Pulley

| Product name | High Torque Timing Pulleys/8YU |

| Part number | GPA50YU8150-A-N30 |

| Features | Circular Tooth Profile Pulleys with little backlash, suitable for positioning. |

* Orange colored cells in the table below indicate the part numbers used in this example.

Selection criteria

Low backlash, light weight pulley.

Back to page top

Available sizes

■High torque timing pulley 8YU type

| Material | Surface treatment | Included

set screw

material |

|

| Pulley | Flange |

| EN AW-2017 Equiv. | EN AW-5052 Equiv. | Clear anodize | EN 1.4301 Equiv. |

| EN 1.1191 Equiv. | Low Carbon Steel | - | Chromium-molybdenum steel

(Black oxide) |

| Black oxide |

■Number of teeth and shaft bore DIA.

| Shape | Applicable belt width | Number of teeth | Pitch circle DIA. | Shaft bore DIA. |

| With hub | 15 ・ 20 ・ 25 | 20 - 60 | Ø50.93 - Ø152.79 | Ø16 - 32 |

| No hub |

* Please see the product pages for details.

Back to page top

Selection steps

■Timing pulley selection steps

- Determining of usage conditions

- Designed power, rotational speed, rotation ratio, interim shaft distance, motion pattern, etc.)

↓

- Pulley (Belt) temporary selection

- Tooth profile・Belt width

↓

- Verification of specifications applicability

-

- Confirmation of calculated shaft distance, etc.

- Confirmation of belt tension and load

Back to page top

Accuracy Info

■Timing pulley accuracy

Shaft bore tolerance: H7

Back to page top

Technical calculations

■Technical calculations

1. https://uk.misumi-ec.com/pdf/fa/p2823.pdf

Back to page top

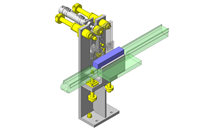

Ball Spline

* Orange colored cells in the table below indicate the part numbers used in this example.

Selection criteria

Used for both linear and rotary motion at the same time

Back to page top

Available sizes

■Ball spline (Both ends tapped)

Spline

shaft | Material | EN 1.3505 Equiv. | EN 1.4125 Equiv. |

| Hardness | 58HRC ~ | 55HRC ~ |

| Nut | Material | EN 1.722515 Equiv. | EN 1.4125 Equiv. |

| Hardness | 58HRC ~ | 55HRC ~ |

| Shape | Round flange | ○ | ○ |

| Compact flange | ○ | - |

| Straight | ○ | ○ |

■Dimensions

| Spline shaft | Nut |

| Name No. | Shaft DIA. | Overall length | Pilot DIA. |

| 6 | Ø6 | 60 - 400 | Ø14 |

| 8 | Ø8 | Ø16 |

| 10 | Ø10.4 | 90 - 600 | Ø21 |

| 13 | Ø13.4 | 100 - 600 | Ø24 |

| 16 | Ø16.6 | 110 - 600 | Ø31 |

* Length selection range will vary according to material and nut configuration.

Please see the product pages for details.

Back to page top

Selection steps

■Ball spline selection steps

- Determine application conditions

- (Load, Torque, Feed distance, Life)

↓

- Temporarily select ball spline specifications

- (Spline shaft DIA., spline shaft length, overall length are temporarily selected based on application conditions.)

↓

- Safety Check

-

Back to page top

Accuracy Info

■Ball spline shaft accuracy

(µm)

Name

No. | Spline

shaft DIA. | Nut O.D. runout | Spline shaft center runout (Max.) |

| (Max.) | Length | - 200 | 201 - 315 | 316 - 400 | 401 - 500 | 501 - |

| 6 | Ø6 | 27 | 72 | 89 | 126 | 163 | - |

| 8 | Ø8 |

| 10 | Ø10.4 | 33 | 59 | 83 | 103 | 82 | 102 |

| 13 | Ø13.4 | 39 | 56 | 71 | 83 | 62 | 75 |

| 16 | Ø16.6 |

Back to page top

Performance info.

■Ball spline rated loads

Name

No. | Basic torque rating | Basic load rating |

| Dynamic (Nm) | Static (Nm) | Dynamic (kN) | Static (kN) |

| 6 | 3.8 | 7 | 1.2 | 2.1 |

| 8 | 4.8 | 8.7 | 1.2 | 2.1 |

| 10 | 11 | 21 | 2.4 | 4.3 |

| 13 | 20 | 37 | 3.3 | 5.9 |

| 16 | 51 | 93 | 6.2 | 11.1 |

Back to page top

Technical calculations

■Ball spline life calculations

Ball spline's running life is calculated with the formula below.

- L: Life (km)

- ft: Temperature factor

- fh: Hardness factor

- fp: Load rating ratio

- fw: Load factor

- L0: Rated life (50km)

- C: Basic dynamic load rating (N)

- F: Applicable radial load (N)

- Ct: Basic dynamic torque rating (N・m)

- T: Applicable torque (N・m)

Ball spline's life time is calculated with the formula below.

- Lh: Run hours (hr)

- L: Life (km)

- St: Stroke length

- n: Cycles per minute (cpm)

■Rated load ratio (fp)

| Name No. | Spline shaft DIA. | Distributed load | Direct download |

| 10 | Ø10.4 | 1 | 0.71 |

| 13 | Ø13.4 | 1 | 0.71 |

| 16 | Ø16.6 | 1 | 0.68 |

■Load factor (fw)

| App. condition | Load factor (fw) |

No vibrations or shocks

(Low speed 1 ~ 2 15m/min or less) | 1 - 2 |

Some vibrations and shocks

(Med. speed 2 ~ 3 60m/min) | 2 - 3 |

Severe vibrations and shocks

(High speed 3 and over 60m/min or over) | 3 - |

Back to page top

Air Gripper

| Product name | Air Gripper/Parallel Type |

| Part number | ACHK6-D |

| Features | Compact Type Pneumatic Grippers with high precision, high rigidity, strong retaining force |

* Orange colored cells in the table below indicate the part numbers used in this example.

Selection criteria

Suitable for gripping small rectangular workpiece

Back to page top

Available sizes

■Small parallel gripper (Sensor mounted type)

| Part name | Material | Surface treatment |

| Main body | EN AW-5056 Equiv. | Clear anodize |

| Jaws ・ attachment mounting | EN 1.1191 Equiv. | Nitriding treatment |

■Specifications and Dimensions

| Operating method | Stroke | Cylinder I.D. | Overall width | Overall height | Overall thickness |

| Single acting ・ Double acting | 4 | Ø8 | 26 | 40.5 | 10 |

| 6 | Ø12 | 30 | 45 | 16.4 |

Back to page top

Accuracy Info

■Small parallel gripper selection steps

- Confirm Design Specifications

- (Confirm required stroke, workpiece weight, etc.)

↓

- Calculations of required gripping force

- 10 ~ 20 times the workpiece weight

(Varies depending on friction coefficient between the jaws and workpiece)

↓

- Selecting a model type and applicability confirmation

-

- ●Gripping method (O.D. gripping ・ I.D. gripping)

- ●Open/close operation method (Single acting ・ Double acting)

- ●Stroke

- ●Gripping points and gripping force

Back to page top

Performance info.

■Small parallel gripper (Sensor mounted type) load info.

| Stroke | Cylinder

I.D. | Operating pressure

range | Effective grip force (N) | Allowable static load rating (N) |

| Single acting (Spring) | Dual acting | F1 | F2 |

| 4 | Ø8 | 0.3 ~ 0.5MPa | 4.2 (1) | 4.9 | 5 | 2.5 |

| 6 | Ø12 | 10.4 (1.9) | 12.2 | 10 | 5 |

Back to page top

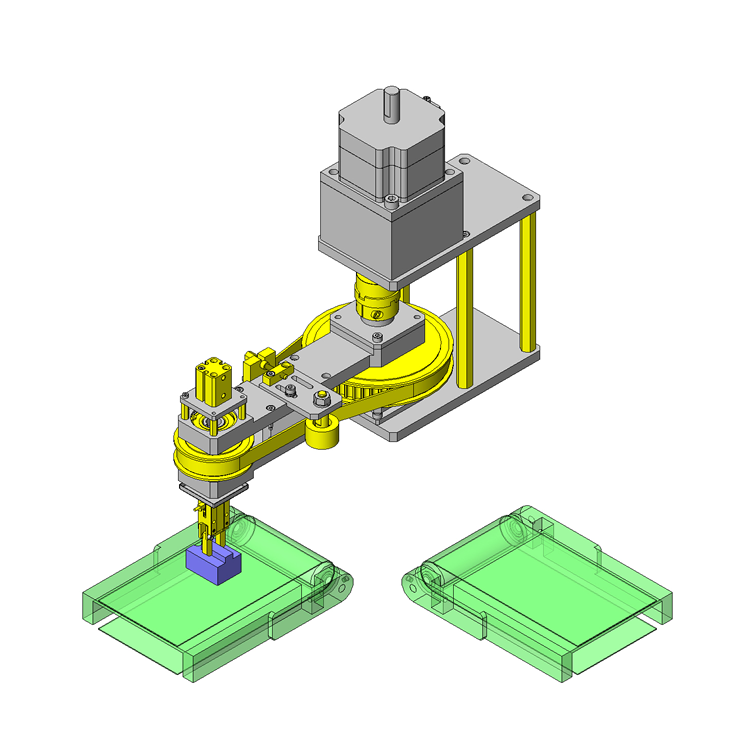

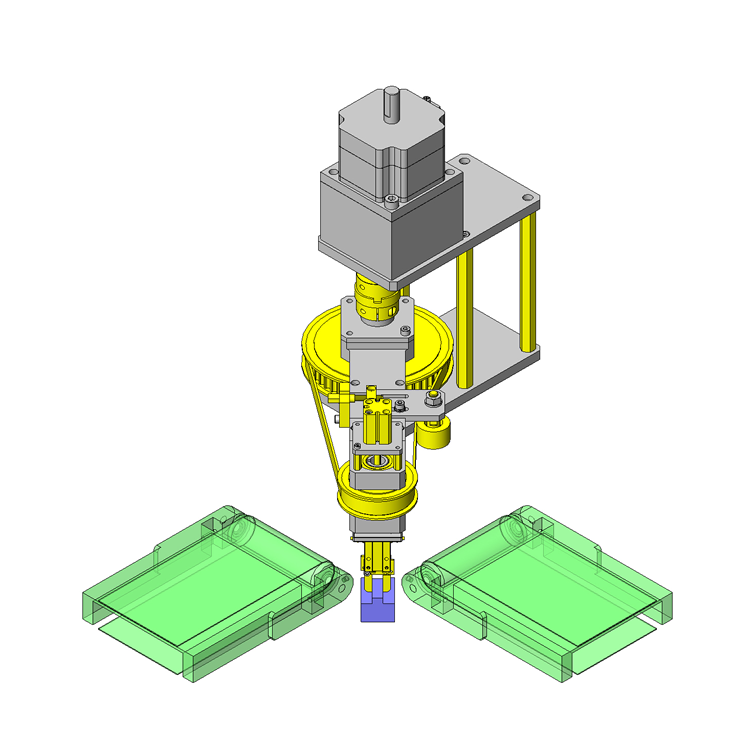

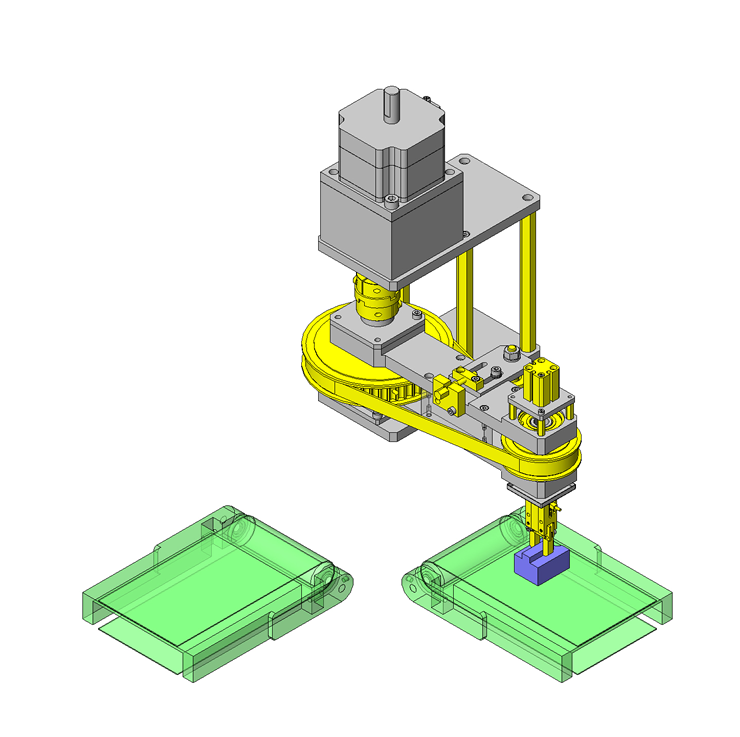

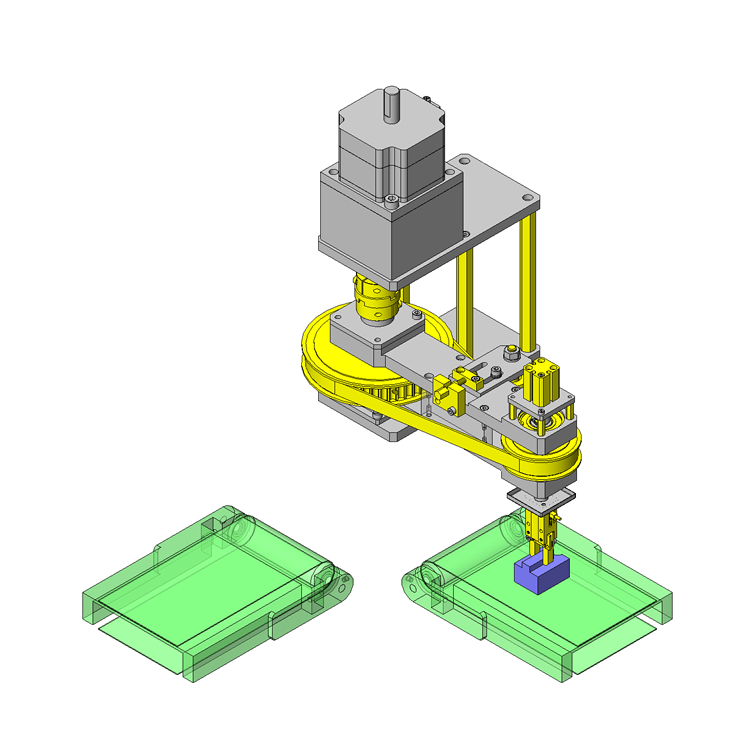

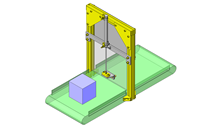

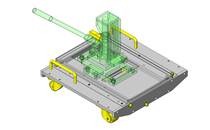

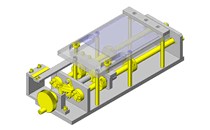

IDEA NOTE One actuator performs swinging and workpiece rotation.

Drive pulley rotates the gripper arm 90°-from one conveyor line to another. Since pulley ration is 2:1, part of the gripper arm rotates 180° (driven pulley translates the motion to ball spline and workpiece gripper).