- inCAD Library Home

- > No.000150 90° Rotational transfer mechanism

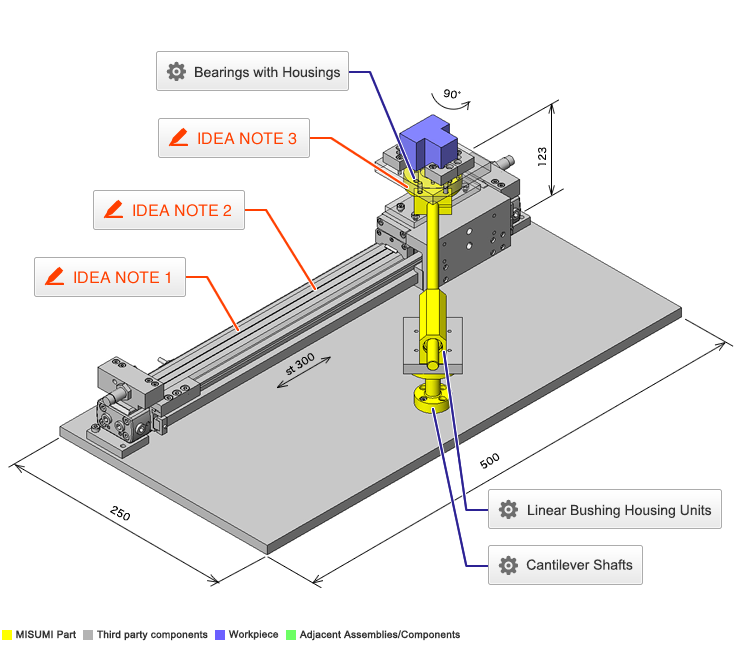

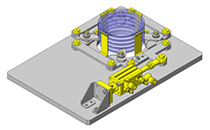

No.000150 90° Rotational transfer mechanism

65

65

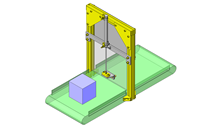

Rotate workpiece 90 degrees while transporting

Related Category

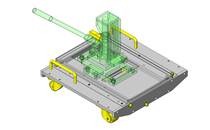

- * Unit assembly CAD data consists of some sub-assemblies.

Each sub-assembly unit can be used as it is or can be edited.

Application Overview

Purpose

- Transfer and rotate a workpiece simultaneously.

Target workpiece

- Shape: Connector

- Size: W40 x D40 x H30mm

- Weight: 150g

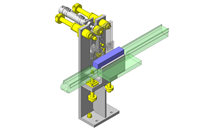

Design Specifications

Operating Conditions or Design Requirements

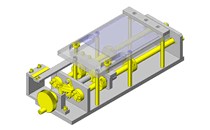

- Horizontal movement stroke: 300mm

- Rotation angle: 90°

- External dimensions: W500 x D250 x H123mm

Required Performance

- Positioning accuracy: ±0.1 / 300mm

- Angle: 90° ±0.05°

Selection Criteria for Main Components

- Ensure that the cylinder with shock absorbing stopper can provide the required positioning accuracy.

Design Evaluation

Verification of main components

- Verify that the cylinder thrust and shock absorber meet the design requirements.

- Conditional values: Friction coefficient of the guide on the rod-less cylinder µ = 0.01, air cylinder efficiency η = 0.82, mass of moving part = 1.6kg, workpiece mass = 150g

- Ø20 cylinder thrust: Fs = 157N at applied pressure of 0.5MPa

- Cylinder thrust necessary to transfer a workpiece F = (0.15 + 1.6) x 0.01 x 9.806 / 0.82 = 0.21N < 157N = Fs

⇒Sufficiently satisfied.

Check the shock absorber capacity. - Conditional values: Stroke of the shock absorber with these specifications St = 8mm, maximum absorbed energy Ea = 7J, Equiv. mass of the colliding object Me = 18kg [atV = 0.5 m/s]

- Check the absorbable kinetic energy.

E = 1 / 2 x m ・ V2 + Fs x St = 1 / 2 x (0.15 + 1.6) x 0.52 + 157 x 0.008 = 1.47J

Ea / 2 = 7J / 2 = 3.5 > 1.47J

⇒One half or less of the maximum absorbable energy. Thus the kinetic energy can be absorbed. - Check the absorbable equivalent mass of the colliding object.

Me = m+2 ・ Fs ・ St / V2 = (0.15 + 1.6) + 2 x 157 x 0.008 / 0.52 = 6.774kg < Me = 18kg

⇒Can be absorbed.

Other Design Consideration

- A cylinder with high mechanical rigidity is selected to meet the requirements for positional accuracy.

Explore Similar Application Examples

Page

-

/

-