- inCAD Library Home

- > No.000140 Table Shuttle Transfer Mechanism

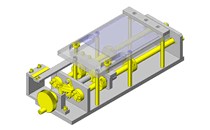

No.000140 Table Shuttle Transfer Mechanism

90

90

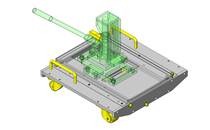

Tables in two tiers halve tact time.

Related Category

- * Unit assembly CAD data consists of some sub-assemblies.

Each sub-assembly unit can be used as it is or can be edited.

Application Overview

Purpose

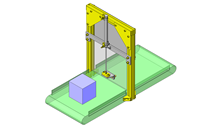

- A single driving mechanism to simultaneously transfer two workpieces in opposite directions.

Points for use

- Automatic mechanism in which a single driving mechanism drives two tables.

Target workpiece

- Workpiece: printed circuit board

- Outer dimensions:W150 x D50 x H3 mm

- Workpiece weight:50g

Design Specifications

Operating Conditions or Design Requirements

- Table Stroke: 385mm

- Outer dimensions: W760 x D350 x H241 mm

Required Performance

- Required accuracy:±0.5mm

Selection Basis for Main Components

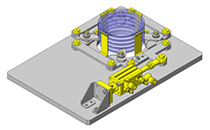

- Stepping motor

- Easy positioning.

Design Evaluation

Verification of main components

- The allowable motor torque is verified to see whether the torque requirement (= load torque + acceleration torque) is satisfied.

- Stepping motor

- Conditional value = allowable motor torque T = 2.7 Nm, transfer mass M = 2.6 kg, acceleration a = 0.385m/s², operation speed NM = 180 [r/min], linear guide friction coefficient μ = 0.1 (take a larger value), acceleration time s = 0.5 s, pulley diameter D = 0.04456 m, pulley reduction ratio i1 = 1, pulley weight m = 0.33 kg, rotor inertia moment = Jo = 120 × 10⁻⁷ [kg•m²], motor reduction ratio i2 = 10, efficiency η = 0.85

- Load in operation direction = F [N ] = Ma = M × (a + μg ) = 2.6 × (0.385 + 0.98) = 3.55

- Load torque TL [N•m] = (F × D)/(2 × η × i1) = (3.55 × 0.04456)/(2 × 0.85 × 1) = 0.093

- Loading moment of inertia JL [kg•m²] = M × (π × D/2 × π)² + (m × D²)/8 = 2.6 × (0.04456/2)² + (0.33 × 0.04456²)/8 = 0.0014

- Acceleration torque Ta [Nm] = ((Jo × i2² + JL)/9.55)) × (NM/s) = ((120 × 10 - 7 × 10² + 0.0014)/9.55) × (180/0.5 ) = 0.098 (9.55 is constant)

- Required torque TM [N・m] = from TL + Ta = 0.093 + 0.098 ≈ 0.19 < 2.7 = T

-> There is no problem.

Other Design Consideration

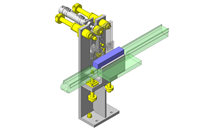

- When the motor is rotated, two belt movement directions can be obtained, and the belt is connected to two tables that can be moved in different directions.

- As the belt design tension of 206N cannot support the allowable overhang load of 50N, bearings are added. The mechanism is assembled using the following steps to protect the motor.

(1) Temporarily tighten the bolts that fix the motor.

(2) Strain the belt.

(3) Finally tighten the bolts to fix the motor. - Positioning accuracy may be low at the end of the travel.

- Table plates are welded for strength and reinforcement.

- As a measure against failure, one microphotosensor is used for home positioning, and another microphotosensor is used for overrun prevention.

- As the upper and lower tables pass each other, there is a risk of injury.

Therefore, the unit should have a cover for the entire mechanism to reduce the operator injury risk.

Explore Similar Application Examples

Page

-

/

-