Rotary Shaft

| Product name | Rotary Shafts/Straight |

| Part number | SSFHR6-35 |

| Features | g6 (ground), h7 (ground) and h9 (polished) are available. Please select based on your applications. |

* Orange colored cells in the table below indicate the part numbers used in this example.

Selection criteria

Can be used as a torque rotary shaft.

Back to page top

Available sizes

■Rotary Shafts - Straight

| O.D. tolerance | Material | Surface Treatment |

|

| h9 (Cold-drawn) | EN 1.1191 Equiv. | Black Oxide |

| Electroless Nickel Plating |

| EN 1.4301 Equiv. | - |

| h7 (Ground) | EN 1.1191 Equiv. | Black Oxide |

| Electroless Nickel Plating |

| EN 1.4301 Equiv. | - |

| g6 (Ground) | EN 1.1191 Equiv. | Black Oxide |

| Electroless Nickel Plating |

| EN 1.4301 Equiv. | - |

EN 1.7220 Equiv.

(Hardness: 30 - 35HRC) | Black Oxide |

| Electroless Nickel Plating |

■Sizes

| O.D. tolerance | Diameter | Tolerance | Length

(Configure in 0.1mm increment) |

| h9 | Ø3 | 0 / -0.025 | 15.0 ~ 150.0 |

| Ø4 | 0 / -0.030 | 15.0 ~ 200.0 |

| Ø5 | 15.0 ~ 250.0 |

| Ø6 | 20.0 ~ 300.0 |

| Ø8 | 0 / -0.036 | 20.0 ~ 400.0 |

| Ø10 | 20.0 ~ 500.0 |

| Ø12 | 0 / -0.043 | 30.0 ~ 600.0 |

| Ø15 | 30.0 ~ 700.0 |

| Ø20 | 0 / -0.052 | 40.0 ~ 800.0 |

| Ø25 | 50.0 ~ 800.0 |

| Ø30 | 60.0 ~ 800.0 |

| Ø35 | 0 / -0.062 | 70.0 ~ 800.0 |

| Ø40 | 80.0 ~ 800.0 |

| Ø50 | 100.0 ~ 800.0 |

| h7 | Ø6 | 0 / -0.012 | 20.0 ~ 300.0 |

| Ø8 | 0 / -0.015 | 20.0 ~ 400.0 |

| Ø10 | 20.0 ~ 500.0 |

| Ø12 | 0 / -0.018 | 30.0 ~ 600.0 |

| Ø15 | 30.0 ~ 700.0 |

| Ø20 | 0 / -0.021 | 40.0 ~ 800.0 |

| Ø25 | 50.0 ~ 800.0 |

| Ø30 | 60.0 ~ 800.0 |

| Ø35 | 0 / -0.025 | 70.0 ~ 800.0 |

| Ø40 | 80.0 ~ 800.0 |

| Ø50 | 100.0 ~ 800.0 |

| g6 | Ø3 | -0.002 / -0.008 | 15.0 ~ 150.0 |

| Ø4 | -0.004 / -0.012 | 15.0 ~ 200.0 |

| Ø5 | 15.0 ~ 250.0 |

| Ø6 | 20.0 ~ 300.0 |

| Ø8 | -0.005 / -0.014 | 20.0 ~ 400.0 |

| Ø10 | 20.0 ~ 500.0 |

| Ø12 | -0.006 / -0.017 | 30.0 ~ 600.0 |

| Ø13 | 30.0 ~ 600.0 |

| Ø15 | 30.0 ~ 700.0 |

| Ø16 | 30.0 ~ 800.0 |

| Ø17 | 40.0 ~ 800.0 |

| Ø18 | 40.0 ~ 800.0 |

| Ø20 | -0.007 / -0.020 | 40.0 ~ 800.0 |

| Ø22 | 40.0 ~ 800.0 |

| Ø25 | 50.0 ~ 800.0 |

| Ø30 | 60.0 ~ 800.0 |

| Ø35 | -0.009 / -0.025 | 70.0 ~ 800.0 |

| Ø40 | 80.0 ~ 800.0 |

| Ø50 | 100.0 ~ 800.0 |

* The size possible to select may vary slightly depending upon the materials. Please see the product pages for details.

Back to page top

Accuracy Info

■Accuracy of Rotary Shafts

| Diameter | Circularity M | Straightness |

| Ø3 ~ 13 | 0.004 | 0.01 / 100 |

| Ø14 ~ 20 | 0.005 |

| Ø21 ~ 40 | 0.006 |

| Ø41 ~ 50 | 0.007 |

■Length Tolerance

| Length | Dimension

Tolerance |

| over | or Less |

| 14 | 30 | ±0.2 |

| 30 | 120 | ±0.3 |

| 120 | 400 | ±0.5 |

| 400 | 800 | ±0.8 |

Back to page top

Small Ball Bearings

| Product name | Small/Deep Groove/Double Shielded with Flange |

| Part number | FL696ZZ |

* Orange colored cells in the table below indicate the part numbers used in this example.

Selection criteria

Suitable for supporting radial motion.

Back to page top

Available sizes

■Small deep groove ball bearings with flange, double shielded

Material: EN 1.3505 Equiv.

| (Name No.) | Shaft Bore Dia. | Outer Cylinder O.D. | Flange O.D. | Overall thickness | Flange

height |

|

| FL682ZZ | Ø2 | Ø5 | Ø6.1 | 2.3 | 0.6 |

| FL692ZZ | Ø6 | Ø7.5 | 3 | 0.8 |

| FL682AZZ | Ø2.5 | Ø6 | Ø7.1 | 2.6 | 0.8 |

| FL692AZZ | Ø7 | Ø8.5 | 3.5 | 0.9 |

| FL673ZZ | Ø3 | Ø6 | Ø7.2 | 2.5 | 0.6 |

| FL683ZZ | Ø7 | Ø8.1 | 3 | 0.8 |

| FL693ZZ | Ø8 | Ø9.5 | 4 | 0.9 |

| FL603ZZ | Ø9 | Ø10.5 | 5 | 1 |

| FL623ZZ | Ø10 | Ø11.5 | 4 | 1 |

| FL674ZZ | Ø4 | Ø7 | Ø8.2 | 2.5 | 0.6 |

| FL684ZZ | Ø9 | Ø10.3 | 4 | 1 |

| FL694ZZ | Ø11 | Ø12.5 | 1 |

| FL604ZZ | Ø12 | Ø13.5 |

| FL624ZZ | Ø13 | Ø15 | 5 |

| FL675ZZ | Ø5 | Ø8 | Ø9.2 | 2.5 | 0.6 |

| FL685ZZ | Ø11 | Ø12.5 | 5 | 1 |

| FL695ZZ | Ø13 | Ø15 | 4 |

| FL605ZZ | Ø14 | Ø16 | 5 |

| FL625ZZ | Ø16 | Ø18 | 5 |

| FL676ZZ | Ø6 | Ø10 | Ø11.2 | 3 | 0.6 |

| FL686ZZ | Ø13 | Ø15 | 5 | 1.1 |

| FL696ZZ | Ø15 | Ø17 | 1.2 |

| FL606ZZ | Ø17 | Ø19 | 6 |

| FL626ZZ | Ø19 | Ø22 | 6 | 1.5 |

| FL678ZZ | Ø8 | Ø12 | Ø13.6 | 3.5 | 0.8 |

| FL688ZZ | Ø16 | Ø18 | 5 | 1.1 |

| FL698ZZ | Ø19 | Ø22 | 6 | 1.5 |

| FL608ZZ | Ø22 | Ø25 | 7 |

| FL6700ZZ | Ø10 | Ø15 | Ø16.5 | 4 | 0.8 |

| FL6800ZZ | Ø19 | Ø21 | 5 | 1 |

| FL6900ZZ | Ø22 | Ø25 | 6 | 1.5 |

| FL6701ZZ | Ø12 | Ø18 | Ø19.5 | 4 | 0.8 |

| FL6801ZZ | Ø21 | Ø23 | 5 | 1.1 |

| FL6901ZZ | Ø24 | Ø26.5 | 6 | 1.5 |

| FL6702ZZ | Ø15 | Ø21 | Ø22.5 | 4 | 0.8 |

| FL6802ZZ | Ø24 | Ø26 | 5 | 1.1 |

| FL6902ZZ | Ø28 | Ø30.5 | 7 | 1.5 |

| FL6703ZZ | Ø17 | Ø23 | Ø24.5 | 4 | 0.8 |

| FL6803ZZ | Ø26 | Ø28 | 5 | 1.1 |

| FL6903ZZ | Ø30 | Ø32.5 | 7 | 1.5 |

| FL6704ZZ | Ø20 | Ø27 | Ø28.5 | 4 | 0.8 |

| FL6804ZZ | Ø32 | Ø35 | 7 | 1.5 |

| FL6904ZZ | Ø37 | Ø40 | 9 | 2 |

| FL6805ZZ | Ø25 | Ø37 | Ø40 | 7 | 1.5 |

| FL6905ZZ | Ø42 | Ø45 | 9 | 2 |

* Please see the product pages for recommended dimensions of the mating shaft.

Back to page top

Performance info.

■Load info of Small deep groove ball bearings with flange, double shielded

| (Name No.) | Shaft Bore Dia. | Outer Cylinder O.D. | Basic Load Rating | Allowable Rotational

Speed rpm

(Reference) |

| Cr (Dynamic) N | Cor (Static) N |

| FL682ZZ | Ø2 | Ø5 | 169 | 50 | 85000 |

| FL692ZZ | Ø6 | 330 | 98 | 75000 |

| FL682AZZ | Ø2.5 | Ø6 | 208 | 74 | 71000 |

| FL692AZZ | Ø7 | 385 | 127 | 63000 |

| FL673ZZ | Ø3 | Ø6 | 208 | 74 | 71000 |

| FL683ZZ | Ø7 | 390 | 130 | 63000 |

| FL693ZZ | Ø8 | 560 | 179 | 60000 |

| FL603ZZ | Ø9 | 570 | 187 | 56000 |

| FL623ZZ | Ø10 | 630 | 218 | 50000 |

| FL674ZZ | Ø4 | Ø7 | 222 | 88 | 60000 |

| FL684ZZ | Ø9 | 640 | 224 | 53000 |

| FL694ZZ | Ø11 | 715 | 276 | 48000 |

| FL604ZZ | Ø12 | 957 | 345 | 48000 |

| FL624ZZ | Ø13 | 1300 | 485 | 40000 |

| FL675ZZ | Ø5 | Ø8 | 217 | 91 | 53000 |

| FL685ZZ | Ø11 | 715 | 281 | 45000 |

| FL695ZZ | Ø13 | 1080 | 430 | 43000 |

| FL605ZZ | Ø14 | 1330 | 505 | 40000 |

| FL625ZZ | Ø16 | 1729 | 670 | 36000 |

| FL676ZZ | Ø6 | Ø10 | 465 | 196 | 45000 |

| FL686ZZ | Ø13 | 1080 | 440 | 40000 |

| FL696ZZ | Ø15 | 1350 | 530 | 40000 |

| FL606ZZ | Ø17 | 2190 | 835 | 38000 |

| FL626ZZ | Ø19 | 2336 | 885 | 32000 |

| FL678ZZ | Ø8 | Ø12 | 515 | 252 | 40000 |

| FL688ZZ | Ø16 | 1610 | 710 | 36000 |

| FL698ZZ | Ø19 | 1990 | 865 | 36000 |

| FL608ZZ | Ø22 | 3350 | 1400 | 34000 |

| FL6700ZZ | Ø10 | Ø15 | 855 | 435 | 15000 |

| FL6800ZZ | Ø19 | 1716 | 840 | 37000 |

| FL6900ZZ | Ø22 | 2695 | 1273 | 34000 |

| FL6701ZZ | Ø12 | Ø18 | 926 | 530 | 13000 |

| FL6801ZZ | Ø21 | 1915 | 1041 | 33000 |

| FL6901ZZ | Ø24 | 2886 | 1466 | 31000 |

| FL6702ZZ | Ø15 | Ø21 | 937 | 582 | 11000 |

| FL6802ZZ | Ø24 | 2073 | 1253 | 28000 |

| FL6902ZZ | Ø28 | 4321 | 2259 | 26000 |

| FL6703ZZ | Ø17 | Ø23 | 1000 | 658 | 9500 |

| FL6803ZZ | Ø26 | 2233 | 1456 | 26000 |

| FL6903ZZ | Ø30 | 4588 | 2565 | 23000 |

| FL6704ZZ | Ø20 | Ø27 | 1041 | 729 | 8500 |

| FL6804ZZ | Ø32 | 4015 | 2462 | 21000 |

| FL6904ZZ | Ø37 | 6381 | 3682 | 19000 |

| FL6805ZZ | Ø25 | Ø37 | 4303 | 2932 | 18000 |

| FL6905ZZ | Ø42 | 7001 | 4540 | 16000 |

Back to page top

Gussets

| Product name | Gussets/Tapped Holes/Standard Holes Position/Standard Perpendicularity Type |

| Part number | RBBW30-30-6 |

* Orange colored cells in the table below indicate the part numbers used in this example.

Selection criteria

Suitable as L-shaped reinforcement

Back to page top

Available sizes

■Rib - Tapped Hole Fixed Dimensions

| Precision Type | Material | Surface Treatment |

Standard Grade

(Perpendicularity: 0.05 / 100)

/

Precision Grade

(Perpendicularity: 0.02 / 100) | EN 1.0038 Equiv. | - |

| Black Oxide |

| Electroless Nickel Plating |

| EN AW-5052 Equiv. | - |

| Clear Anodize |

| Black Anodize |

| EN 1.4301 Equiv. | - |

■Sizes and Dimensions

| Precision Type | Short side | Long side | Thickness / Tapped Hole Dia. | Tapped

Hole Depth |

| 30 | 40 | 50 | 60 | 80 | 100 | EN 1.0038 Equiv. / EN 1.4301 Equiv. | EN AW-5052 Equiv. |

| t6 | t9 | t12 | t16 | t6 | t10 | t12 | t16 |

Standard Grade

(Perpendicularity: 0.05 / 100)

/

Precision Grade

(Perpendicularity: 0.02 / 100) | 20 | ○ | ○ | ○ | ○ | ○ | | M3 | | | | M3 | | | | Diameter x 1.5 |

| 30 | ○ | | | | | | M3 | | M6 | | M3 | | M6 | |

| ○ | ○ | ○ | ○ | ○ | | M5 | M6 | | | M5 | M6 | |

| 40 | | ○ | ○ | ○ | ○ | ○ | | M5 | M6 | | | M5 | M6 | |

| | | | | | | | M6 | M8 | | | M6 | M8 |

| 50 | | | ○ | ○ | ○ | ○ | | M5 | M6 | | | M5 | M6 | |

| | | | | | | | M6 | M8 | | | M6 | M8 |

| 60 | | | | ○ | ○ | ○ | | M5 | M6 | | | M5 | M6 | |

| | | | | | | | M6 | M8 | | | M6 | M8 |

| 80 | | | | | ○ | ○ | | M5 | M6 | M8 | | M5 | M6 | M8 |

| | | | | | | | M6 | M8 | | | M6 | M8 |

| ## | | | | | | ○ | | M5 | M6 | M8 | | M5 | M6 | M8 |

| | | | | | | | M6 | M8 | | | M6 | M8 |

Back to page top

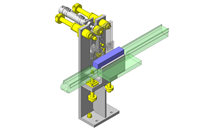

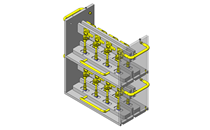

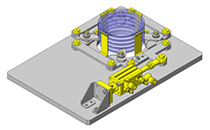

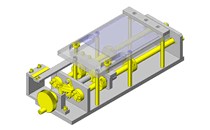

IDEA NOTE Reducing moment generated on the motor shaft.

Wire winding drum is fixed on each end, one on the motor axis and second end on shaft supported by bearing.