- inCAD Library Home

- > No.000179 Centering mechanism utilizing floating joint

No.000179 Centering mechanism utilizing floating joint

13

13

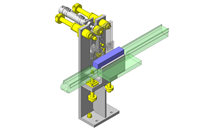

Correction of angular misalignment generated by the suction cup

Related Category

- * Unit assembly CAD data consists of some sub-assemblies.

Each sub-assembly unit can be used as it is or can be edited.

Application Overview

Purpose

- Purpose

- Correction of angular misalignment of workpiece.

- Operation

- Descend the arm so that the suction cups attach to a workpiece. The suction cup surface will follow the tilt of the workpiece because of the allowable angular misalignment tolerance of the floating joint. Once the workpiece is suctioned, lift the workpiece so that the angular misalignment is restored. Angular misalignment is restored by repulsive force of the spring plungers.

Target workpiece

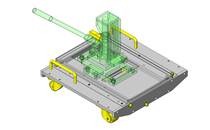

- Shape: Flat plates such as circuit boards, etc.

- Size: W200 x L200 x H0.8mm

- Weight: 500g

Design Specifications

Operating Conditions or Design Requirements

- Arm upper surface - Suction cup surface: 57mm

- External size: W341 x D142 x H58mm

- Allowable lateral misalignment: 0.5, allowable angular misalignment: 4°;

Required Performance

- Locating accuracy: ±1mm

Selection Criteria for Main Components

- Floating joint: Shall have lateral misalignment tolerance and angular misalignment tolerance.

- Suction cup: Shall not exceed the allowable weight of the floating joint.

Design Evaluation

Verification of main components

- Verify the suction force is sufficient to hold workpiece.

- Work retention weight

- Conditional values: maximum tension using force of the floating joint: F1 = 500N

Suction holder pad diameter: D = 1.5cm

Vacuum level: P = -60kPa

Number of suction holders: n = 4 [pieces], Horizontal sling safety factor: f = 4, gravitational acceleration: g = 9.8N/m²

Pad area: C = D2 x (π / 4) = 1.77cm²

Suction force per suction holder: W = { (C x P) / 101} x 10.13 x (1 / f) Thus, W = 2.66N

Suction force with 4 suction holders: W' = 4 x W = 10.6N - F1 >> W" Thus, sufficiently safe for the floating joint.

- Maximum weight of the workpiece = W' /g = 1.08kg Thus, safe against workpiece weight of 500g.

- Conditional values: maximum tension using force of the floating joint: F1 = 500N

Other Design Consideration

- The overall unit height can be reduced by using a floating joint.

- Roughness of cone-shaped plunger support may hinder level restoration and centering. Make sure the finish is Ra 1.6 or better.

Explore Similar Application Examples

Page

-

/

-