- inCAD Library Home

- > No.000023 Cutting Unit

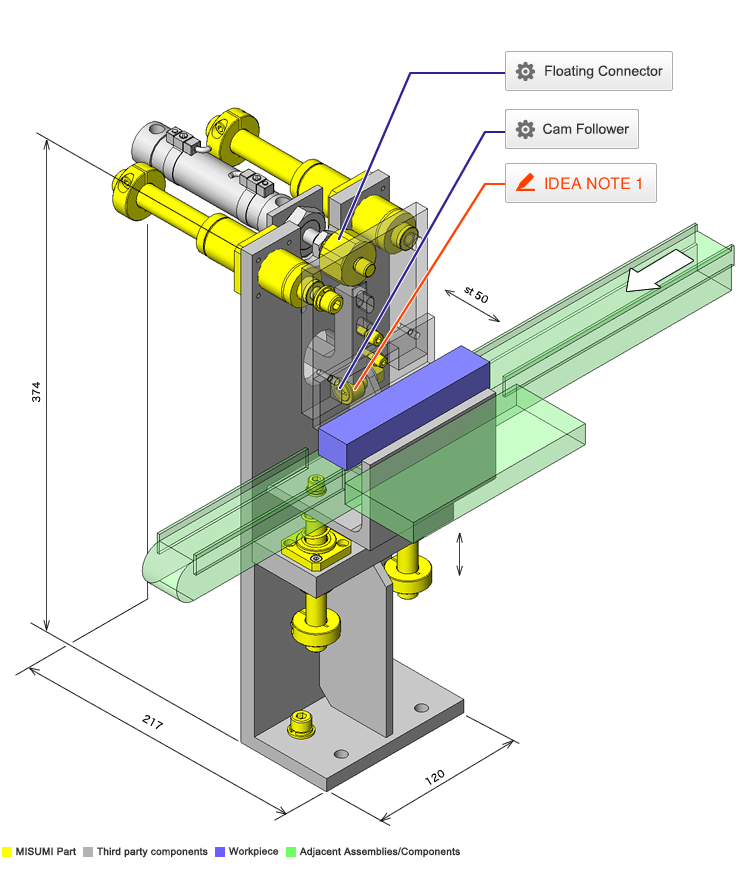

No.000023 Cutting Unit

48

48

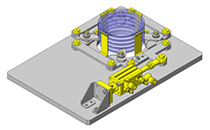

Double acting cylinder mechanism with cam follower

Related Category

- * Unit assembly CAD data consists of some sub-assemblies.

Each sub-assembly unit can be used as it is or can be edited.

Application Overview

Purpose

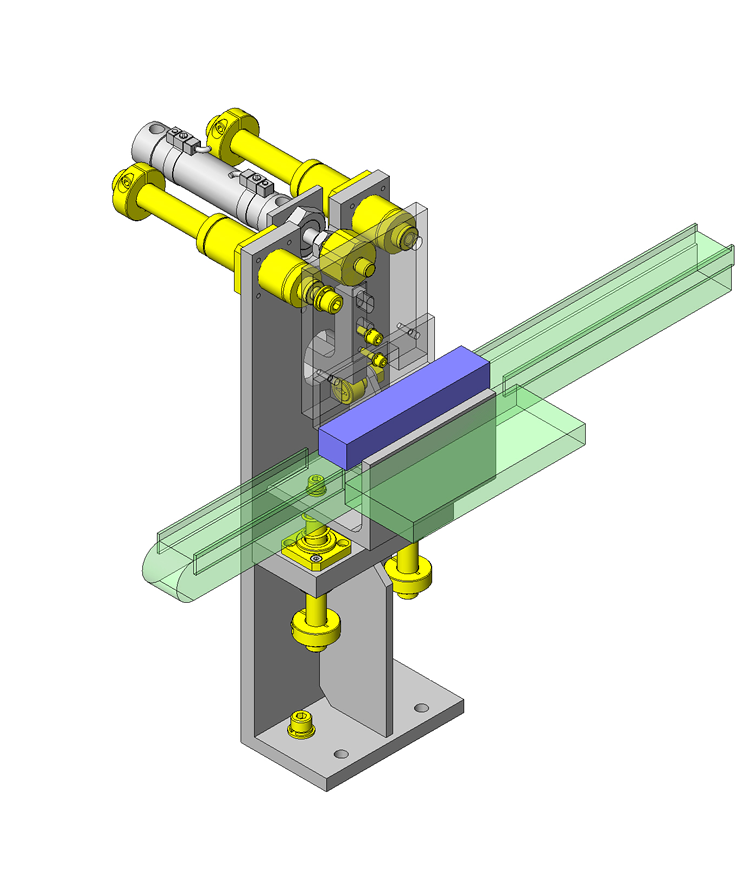

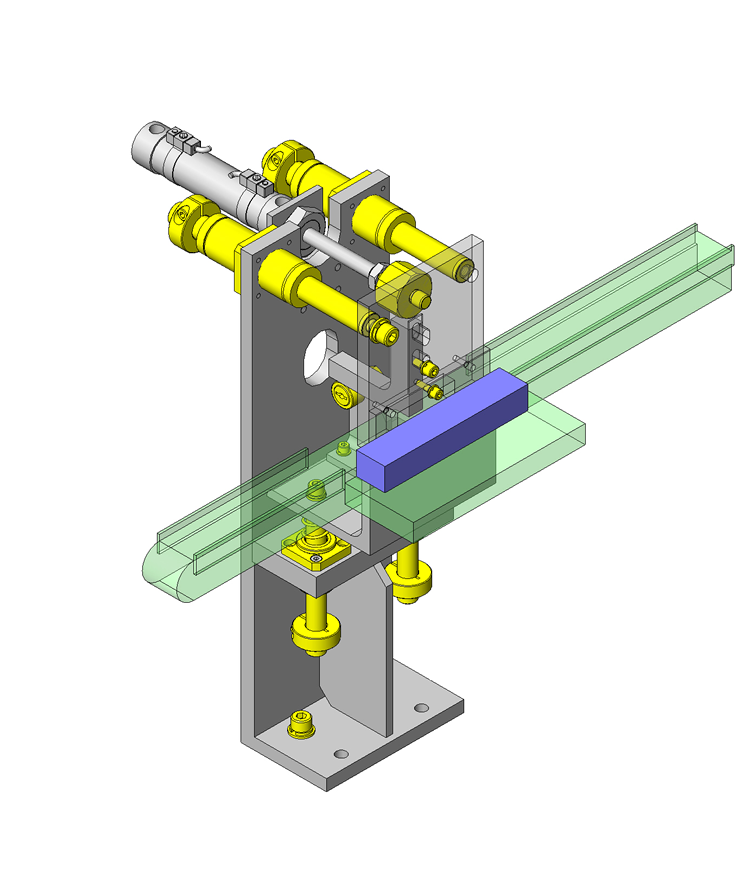

- A cut-to-length process that incorporates an open / close guidance system made using a double acting cylinder and cam mechanism.

- Operation order: (1) The cylinder pushes out (2) Cam driven shutter opens (3) Workpiece is cut (4) The cylinder returns (5) Cam driven shutter closes

Target workpiece

- Plastic case

Dimensions: W125 x D25 x H20

Workpiece weight: 0.08kg

Design Specifications

Operating Conditions or Design Requirements

- Stroke 50mm

- External dims.: W120 x D217 x H374

Required Performance

- Spring compression load: 20N

Spring constant: 1.0N/mm

Selection Criteria for Main Components

- Spring

- Select a set of springs with load ratings that are higher than that of the weights being supported above them.

- Cylinder

- Select a double acting cylinder with sufficient force rating to push against the springs.

Design Evaluation

Verification of main components

- Ensure the selected cylinder is able to generate a force adequate to push down on the springs.

- Spring

- Load = Spring constant x Deflection amount x Quantity used = 1.0N/mm x 10mm x 2pcs. = 20N > 9.6N (Load applied upon the springs) .

- Cylinder

- Select a cylinder that can generate 40N ( = 20 x 2: x 2 Safety margin) vertically.

- Select a cylinder with 90N force from the catalog, and obtain the tube inner diameter dmm.

- Tube inner diameter dmm = √ (Force x 4 / (Load factor x Pressure used x π)) = √ (90N x 4 / (0.5 x 0.4MPa x π)) = 23.9mm.

- Therefore a cylinder of Ø25mm is selected.

Other Design Consideration

- A pusher mechanism for the next section of the workpiece.

- Timing between shutter opening and cutting of the workpiece.

Explore Similar Application Examples

Page

-

/

-