- inCAD Library Home

- > No.000117 Multi-Stroke Cam Mechanism

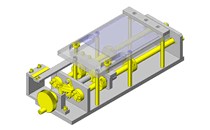

No.000117 Multi-Stroke Cam Mechanism

15

15

Multiple-step stroke with a minimum actuator

Related Category

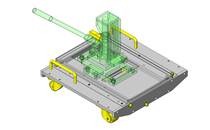

- * Unit assembly CAD data consists of some sub-assemblies.

Each sub-assembly unit can be used as it is or can be edited.

Application Overview

Purpose

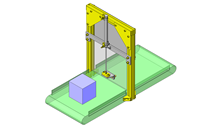

- To transfer workpiece using multiple steps.

- [Operation]

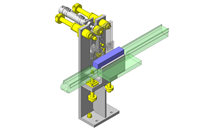

A linear movement/rotation actuator is used as a drive to preform a multi-step stroke with the help of an eccentric tapered cam.

The details of the multi-step stroke are shown below.

Position 1: Initial state in which the actuator is not operated.

Position 2: State in which the eccentric cam is rotated by 180° by the rotary stroke of the actuator.

Position 3: Tapered cam is moved 29.8mm by the linear stroke of the actuator.

Target workpiece

- Shape: circuit board carrier, tray.

size: W48 x D80 x H54mm.

weight: 0.6kg.

Design Specifications

Operating Conditions or Design Requirements

- Outer dimensions: W135 x D500 x H232.5mm

- Vertical stroke: 30mm

- Cylinder stroke: 29.8mm

Required Performance

- Weight: 1.1kg.

Selection Criteria for Main Components

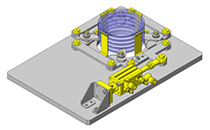

- Swing cylinder.

- Torque of 0.4 N・m or more at oscillation angle of 180 degrees.

- Thrust in horizontal direction of 30 N or higher.

Design Evaluation

Verification of main components

- Verify if the cylinder can withstand the load torque and weight of the workpiece.

- Lifting thrust.

- Conditional value: workpiece mass W1 = 1.1 kg, gravitational acceleration g = 9.8 m/s ².

Cylinder thrust: F1 = 196 N, angle of eccentric cam: θ1 = 20°

Cylinder lifting thrust: F2 = F1/tan20° = 196/tan20° = 538.5N

Load F3 = Wg = 1.1 x 9.8 = 10.1N

F2 > F3.

- Conditional value: workpiece mass W1 = 1.1 kg, gravitational acceleration g = 9.8 m/s ².

- Torque.

- Conditional value: cylinder effective torque T1 = 0.422 N・m (air pressure 0.4 MPa),

Maximum distance from eccentric cam to load on the drawing when cylinder has stroked by 29.8 mm L1 = 0.0325 m

Load torque T2 = F3 x L1 = 0.328 N・m

T1 > T2.

- Conditional value: cylinder effective torque T1 = 0.422 N・m (air pressure 0.4 MPa),

Other Design Consideration

- By setting the length of the eccentric portion of the cam as twice the length of the vertical stroke produced by the taper, equal stroke is enabled.

Explore Similar Application Examples

Page

-

/

-