- inCAD Library Home

- > No.000148 Intermittent Rotation Mechanism

No.000148 Intermittent Rotation Mechanism

181

181

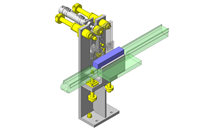

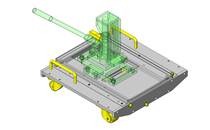

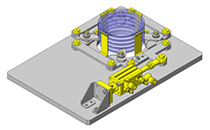

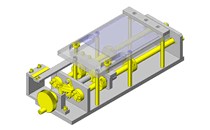

Cylinder-driven index table

Related Category

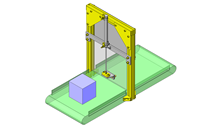

- * Unit assembly CAD data consists of some sub-assemblies.

Each sub-assembly unit can be used as it is or can be edited.

Application Overview

Purpose

- Purpose

- To rotate 8-position index table to process workpiece.

- Operation

- Performs angle feed of turn table.

- By retracting the cylinder, removes the indexing finger from the groove of indexing gear.

- As the cylinder is extruded, the ratchet claw is engaged with the ratchet gear, causing the index table to rotate. The tension spring keeps pressing the ratchet claw against the ratchet gear.

- The cylinder inserts the indexing claw in the groove of the indexing gear to perform rotational positioning. Retracts cylinder.

Target workpiece

- Shape: connector

- Size: W50 x D50 x H30mm

- Weight: 0.15kg

Design Specifications

Operating Conditions or Design Requirements

- Movement angle: 45 degrees

- Division by 360/8 degrees

- Cylinder stroke: 100mm

- Stopper stroke: 10mm

- Outer dimensions: Ø600 x H114mm

Selection Criteria for Main Components

- Selected an air cylinder that has the thrust specification required to rotate the index table 45 degrees in 1 second.

Design Evaluation

Verification of main components

- The cylinder thrust is verified to see whether it can withstand the workpiece load.

- Here, calculation for selecting air cylinder thrust is explained.

- Conditional value: angle θ = 45degrees, movement time t = 1sec., link arm length L = 0.125m, moment of inertia applied to air cylinder I = 0.5492kg・m²

- As uniform acceleration motion is assumed as angular velocity here, θ: oscillating angle (rad), 45° = 2π / 8rad

- Angular velocity after t seconds: ω = 2・θ / t = 2 x (2π / 8) / 1 = 1.571rad/sec

- Equation of rotary motion: from I・ω = M and M = F・L, cylinder thrust F = I・ω / L = 0.5492 x 1.571 / 0.125 = 6.9N

- Theoretical thrust of Ø40 air cylinder: 628 (N) when air pressure in use is 0.5MPa

-> As F = 6.9 (N) ≤ 628 (N), this is acceptable.

Other Design Consideration

- The ratchet mechanism shall have a sufficient strength.

The bending stress shall be 29 (N/mm²) or less and the shearing stress shall be 24.7 (N/mm²) or less. - For the strength of the indexing positioning part, the required torque shall be considered.

Explore Similar Application Examples

Page

-

/

-