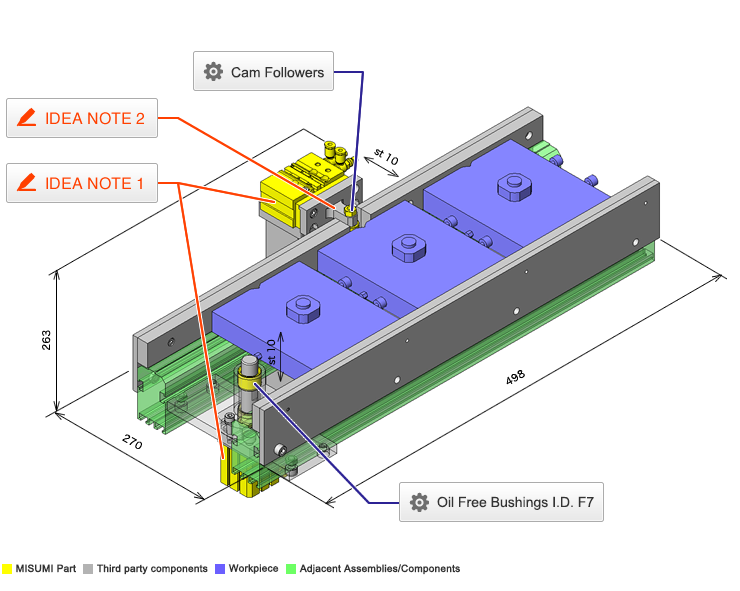

Cam Followers

| Product name | Cam Followers/Hex Hole/Flat Type/No Seal |

| Part number | CFFAS6-16 |

* Orange colored cells in the table below indicate the part numbers used in this example.

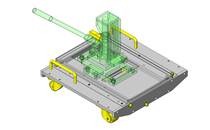

Selection criteria

Centering is achieved, even if with some misalignment, when cam follower hits somewhere in the range of inclined part of V Groove.

Back to page top

Available sizes

■Cam Followers - Hex Hole, No Seal, Flat Type

| Purpose | Main Body | Nut |

| Material | Seal | Material | Surface Treatment |

| N/A | Yes |

| General | EN 1.3505 Equiv. | ○ | ○ | EN 1.1191 Equiv. | Black Oxide |

| EN 1.4125 Equiv. | ○ | ○ | EN 1.4301 Equiv. | - |

| Low particle generation | - | ○ |

■Sizes and Dimensions

| Stud Dia. | Thread Dia. x Pitch | Outer Ring Dia. | Outer Ring Width | Overall Length |

| Ø3 | M3 x 0.5 | Ø10 | 7 | 17 |

| Ø4 | M4 x 0.7 | Ø12 | 8 | 20 |

| Ø5 | M5 x 0.8 | Ø13 | 9 | 23 |

| Ø6 | M6 x 1.0 | Ø16 | 11 | 28 |

| Ø8 | M8 x 1.25 | Ø19 | 11 | 32 |

| Ø10 | M10 x 1.25 | Ø22 | 12 | 36 |

| Ø26 |

| Ø12 | M12 x 1.5 | Ø30 | 14 | 40 |

| Ø32 |

Back to page top

Accuracy Info

■Cam follower accuracy

Stud Dia. Tolerance: h7

Outer Ring Width Tolerance: 0/-0.12

Outer Race Dia. Tolerance:

| Outer Ring Dia. | Tolerance |

| Ø10 | 0/-0.008 |

| Ø12 |

| Ø13 |

| Ø16 |

| Ø19 | 0/-0.009 |

| Ø22 |

| Ø26 |

| Ø30 |

| Ø32 | 0/-0.011 |

Back to page top

Performance info.

Load capacity and rotation speed of cam follower

Stud Dia.

- Outer Ring Dia. | Basic Dynamic Load Rating C (kN) | Basic Static Load Rating Cor (kN) | Max. Allowable Load (kN) | Track Load Capacity (kN) | Rotational speed limit (rpm) |

| With Seal | Without Seal |

| Ø3-Ø10 | 1.47 | 1.18 | 0.36 | 1.37 | 32900 | 47000 |

| Ø4-Ø12 | 2.06 | 2.05 | 0.78 | 1.76 | 25900 | 37000 |

| Ø5-Ø13 | 3.14 | 2.77 | 1.42 | 2.25 | 20300 | 29000 |

| Ø6-Ø16 | 3.59 | 3.58 | 2.11 | 3.43 | 17500 | 25000 |

| Ø8-Ø19 | 4.17 | 4.65 | 4.73 | 4.02 | 14000 | 20000 |

| Ø10-Ø22 | 5.33 | 6.78 | 5.81 | 4.7 | 11900 | 17000 |

| Ø10-Ø26 | 5.49 |

| Ø12-Ø30 | 7.87 | 9.79 | 9.37 | 7.06 | 9800 | 14000 |

| Ø12-Ø32 | 7.45 |

Back to page top

Oil Free Bushings I.D. F7

| Product name | Oil Free Bushings/Copper Alloy/Standard/I.D. F7/O.D. m6 |

| Part number | MPBZ15-15 |

| Features | The most standard type in the Copper Alloy series. |

* Orange colored cells in the table below indicate the part numbers used in this example.

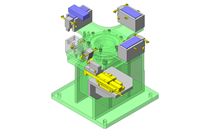

Selection criteria

Provides high friction resistance in the environment where oil film formation is discouraged by reciprocating motions or frequent starts and stops, without lubrication.

Back to page top

Available sizes

■Oil Free Bushings I.D. F7 - Copper Alloy

Material: High Tensile Brass Alloy, Solid Lubricant Embedded

■Sizes and Dimensions

| I.D.(mm) | Overall Length | O.D. |

| 8 | 9 | 10 | 12 | 15 | 16 | 19 | 20 | 25 | 30 | 35 | 40 | 50 | 60 | 70 | 80 | 100 |

| 5 | ○ | ○ | ○ | ○ | ○ | - | - | - | - | - | - | - | - | - | - | - | - | 9 |

| 6 | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | - | - | - | - | - | - | - | - | - | 10 |

| 8 | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | - | - | - | - | - | - | - | - | 12 |

| 10 | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | - | - | - | - | - | - | - | 14 |

| 12 | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | - | - | - | - | - | - | 18 |

| 13 | - | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | - | - | - | - | - | - | 19 |

| 15 | - | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | - | - | - | - | - | 21 |

| 16 | - | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | - | - | - | - | - | 22 |

| 18 | - | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | - | - | - | - | - | 24 |

| 20 | - | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | - | - | - | 28 |

| 20A | - | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | - | - | - | - | 30 |

| 25 | - | - | - | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | - | - | - | 33 |

| 25A | - | - | - | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | - | - | - | 35 |

| 30 | - | - | - | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | - | - | 38 |

| 35 | - | - | - | - | - | - | - | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | - | - | 44 |

| 40 | - | - | - | - | - | - | - | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | - | 50 |

| 50 | - | - | - | - | - | - | - | - | - | ○ | ○ | ○ | ○ | ○ | ○ | ○ | - | 62 |

| 60 | - | - | - | - | - | - | - | - | - | - | - | - | ○ | ○ | ○ | ○ | - | 75 |

| 80 | - | - | - | - | - | - | - | - | - | - | - | - | - | ○ | ○ | ○ | - | 96 |

| 100 | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | ○ | ○ | 120 |

Back to page top

Accuracy Info

■Accuracy of Oil Free Bushings (Copper Alloy Straight Standard Type)

| I.D.(mm) | I.D. Tolerance (F7) | O.D. | O.D. Tolerance (m6) |

|

| 5 | +0.022

+0.010 | 9 | +0.015

+0.006 |

| 6 | 10 |

| 8 | +0.028

+0.013 | 12 | +0.018

+0.007 |

| 10 | 14 |

| 12 | +0.034

+0.016 | 18 |

| 13 | 19 | +0.021

+0.008 |

| 15 | 21 |

| 16 | 22 |

| 18 | 24 |

| 20 | +0.041

+0.020 | 28 |

| 20A | 30 |

| 25 | 33 | +0.025

+0.009 |

| 25A | 35 |

| 30 | 38 |

| 35 | +0.050

+0.025 | 44 |

| 40 | 50 |

| 50 | 62 | +0.030

+0.011 |

| 60 | +0.060

+0.030 | 75 |

| 80 | 96 | +0.035

+0.013 |

| 100 | +0.071

+0.036 | 120 |

Back to page top

Performance info.

■Load Information of Oil Free Bushings (Copper Alloy Straight Standard Type)

| Regular | Non-lubricated |

| Maximum Allowable Load | 29.0N/mm² |

| Maximum Allowable Velocity | 60m/min | 30m/min |

Back to page top

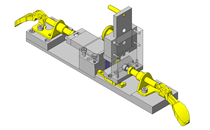

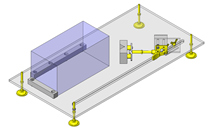

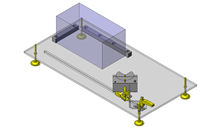

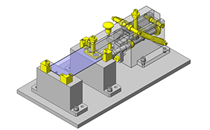

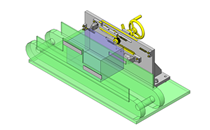

IDEA NOTE A cylinder is used to drive the stopper/blocker.

Due to the compact size of the cylinder, it can be used in a tight space.

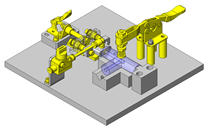

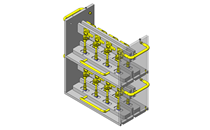

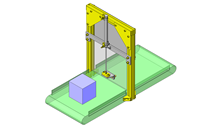

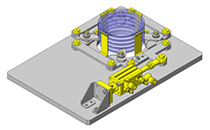

IDEA NOTE Blocking: V groove + cam follower

Blocking is possible - even with a slight displacement - if the cam follower makes contact within the range of the oblique portion of the V groove.